In the world of construction and industrial applications, material selection plays a crucial role in determining the longevity and performance of structures. Among the various structural steel options available, stainless steel channel stands out as a superior choice for projects requiring exceptional durability, corrosion resistance, and long-term reliability. This versatile structural component has become increasingly popular across industries ranging from food processing to marine construction, where environmental challenges demand materials that can withstand harsh conditions while maintaining their structural integrity over decades of service.

The decision to invest in high-quality structural materials often determines whether a project will require frequent maintenance, early replacement, or continue performing optimally for its intended lifespan. Understanding the unique properties and advantages of stainless steel channel systems helps engineers, contractors, and facility managers make informed decisions that balance initial costs with long-term value. Modern manufacturing processes have made these premium materials more accessible while maintaining the exceptional quality standards that have made stainless steel the preferred choice for critical applications worldwide.

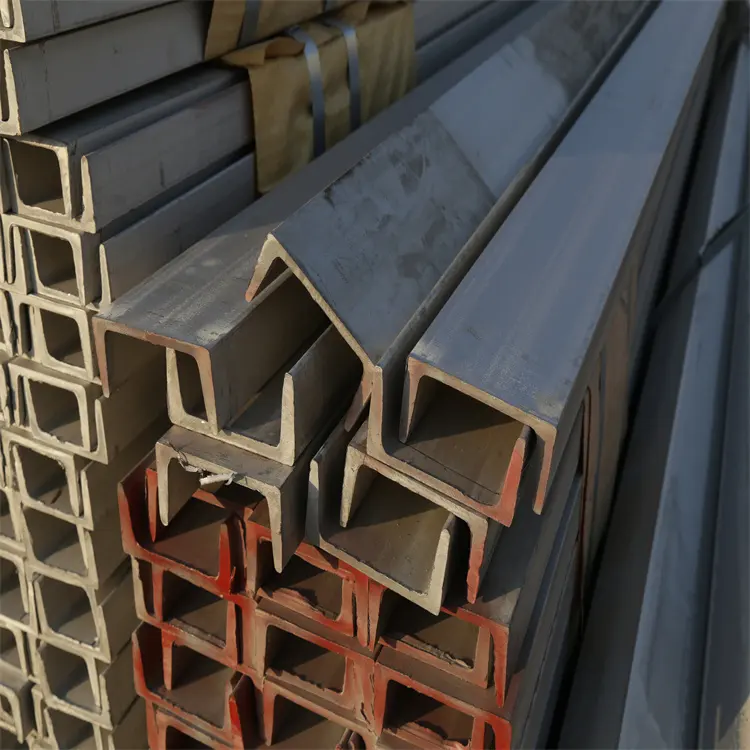

Corrosion Resistance and Environmental Protection

Superior Oxidation Resistance

The primary advantage of stainless steel channel lies in its exceptional resistance to oxidation and corrosion. Unlike conventional carbon steel, which forms rust when exposed to moisture and oxygen, stainless steel develops a passive chromium oxide layer that protects the underlying metal from further deterioration. This self-healing protective barrier continuously regenerates when damaged, ensuring consistent performance even in challenging environmental conditions. The chromium content, typically ranging from 10.5% to 30% depending on the grade, creates this invisible shield that prevents moisture penetration and oxidative damage.

This natural corrosion resistance becomes particularly valuable in applications where regular maintenance access is limited or costly. Structures exposed to coastal environments, chemical processing facilities, or areas with high humidity benefit significantly from the inherent protective properties of stainless steel channel systems. The material maintains its structural integrity and appearance without requiring protective coatings, painting, or frequent replacement cycles that burden facility budgets and operational schedules.

Chemical and Environmental Durability

Beyond basic oxidation resistance, stainless steel channel demonstrates remarkable durability when exposed to various chemical environments. Different grades offer specific resistance profiles, with austenitic grades like 316L providing enhanced protection against chloride-induced corrosion, while ferritic grades excel in applications involving sulfur compounds or reducing acids. This chemical compatibility makes stainless steel channel an ideal choice for industrial facilities processing chemicals, pharmaceuticals, or food products where contamination prevention is critical.

Temperature fluctuations that would compromise other materials have minimal impact on properly selected stainless steel channel grades. The material maintains its mechanical properties across a wide temperature range, from cryogenic applications to high-temperature industrial processes. This thermal stability eliminates concerns about expansion-related failures or strength degradation that commonly affect carbon steel structures in demanding environments.

Structural Performance and Engineering Advantages

Load-Bearing Capabilities

Engineering applications demand materials that provide reliable load-bearing performance throughout their service life. Stainless steel channel offers excellent strength-to-weight ratios, allowing designers to create efficient structural frameworks that minimize material usage while maximizing performance. The uniform grain structure achieved through modern manufacturing processes ensures consistent mechanical properties along the entire length of each channel section, eliminating weak points that could compromise structural integrity under load.

The ductility characteristics of stainless steel channel provide additional safety margins in structural applications. Unlike brittle materials that fail suddenly under excessive loads, stainless steel exhibits plastic deformation behavior that provides visible warning signs before ultimate failure. This progressive failure mode allows for timely intervention and repair, preventing catastrophic structural collapse and enhancing overall safety in critical applications.

Dimensional Stability and Precision

Precision manufacturing processes ensure that stainless steel channel sections maintain tight dimensional tolerances throughout their service life. The material's low thermal expansion coefficient minimizes dimensional changes due to temperature variations, ensuring that connections, alignments, and clearances remain within acceptable limits over extended periods. This dimensional stability proves particularly valuable in precision manufacturing equipment, architectural applications, and infrastructure projects where maintaining exact measurements is critical for proper operation.

The smooth surface finish achievable with stainless steel channel reduces friction in mechanical applications and facilitates easy cleaning in hygienic environments. Surface roughness values can be controlled during manufacturing to meet specific application requirements, from mirror-polished surfaces for pharmaceutical equipment to textured finishes for enhanced grip in walkway applications. This versatility in surface treatment options expands the range of suitable applications while maintaining the underlying durability benefits.

Cost-Effectiveness and Lifecycle Value

Initial Investment Considerations

While stainless steel channel typically requires higher initial investment compared to carbon steel alternatives, comprehensive lifecycle cost analysis consistently demonstrates superior value over extended service periods. The elimination of protective coating requirements, reduced maintenance intervals, and extended service life create significant cost savings that offset the premium initial material costs. Projects with 20-year or longer design lives particularly benefit from this long-term cost advantage.

Budget planning becomes more predictable when using stainless steel channel systems due to their consistent performance characteristics and minimal maintenance requirements. Unlike coated steel systems that require periodic recoating, inspection, and replacement of corroded sections, stainless steel channel installations maintain their performance with basic cleaning and routine inspections. This predictability allows facility managers to allocate maintenance budgets more effectively while reducing unexpected repair costs.

Maintenance and Operating Cost Benefits

The low maintenance requirements of stainless steel channel translate directly into reduced operating costs and improved facility uptime. Cleaning procedures typically involve simple washing with mild detergents or steam cleaning, eliminating the need for specialized chemicals, abrasive cleaning methods, or protective equipment required for maintaining painted steel structures. The non-porous surface resists bacterial growth and contamination, making it ideal for food processing, pharmaceutical, and healthcare facilities where hygiene standards are paramount.

Inspection procedures for stainless steel channel systems focus on mechanical connections and load-bearing assessments rather than corrosion monitoring and coating condition evaluation required for carbon steel structures. This simplified inspection process reduces both labor costs and facility downtime while providing confidence in continued structural integrity. The ability to perform visual inspections without specialized equipment or surface preparation further enhances the operational advantages of stainless steel channel installations.

Manufacturing Quality and Grade Selection

Material Grade Optimization

Selecting the appropriate stainless steel grade for channel applications requires understanding the specific environmental and mechanical demands of each project. Austenitic grades like 304 and 316L offer excellent general-purpose performance with superior formability and weldability, making them suitable for most structural applications. The 316L grade provides enhanced chloride resistance for coastal or chemical environments, while 304 remains cost-effective for indoor applications with moderate environmental exposure.

Duplex stainless steels combine the benefits of austenitic and ferritic structures, providing higher strength levels that allow for reduced material thickness in load-bearing applications. These advanced grades offer exceptional resistance to stress corrosion cracking and chloride-induced pitting, making them ideal for offshore platforms, chemical processing equipment, and other demanding environments where standard austenitic grades might prove inadequate.

Manufacturing Process Excellence

Modern stainless steel channel manufacturing employs advanced rolling and forming techniques that maintain the material's beneficial properties while achieving precise dimensional control. Hot rolling processes followed by controlled cooling create uniform grain structures that optimize both mechanical properties and corrosion resistance. Surface finishing operations remove any scale or contamination that could compromise long-term performance while achieving the desired surface characteristics for specific applications.

Quality control procedures throughout the manufacturing process ensure that each stainless steel channel section meets specified chemical composition, mechanical properties, and dimensional requirements. Comprehensive testing protocols including chemical analysis, tensile testing, and dimensional verification provide documentation of compliance with relevant standards and specifications. This rigorous quality assurance approach ensures consistent performance across all delivered materials and eliminates concerns about substandard components compromising project integrity.

Installation and Fabrication Advantages

Welding and Joining Techniques

Stainless steel channel offers excellent weldability when proper techniques and filler materials are employed. The availability of matching composition welding wires and electrodes ensures that welded joints maintain the same corrosion resistance and mechanical properties as the base material. Proper heat input control and post-weld cleaning procedures preserve the passive layer integrity, maintaining long-term durability at connection points where failures commonly occur in other material systems.

Mechanical fastening options for stainless steel channel include both permanent and removable connection methods using compatible stainless steel fasteners. The galvanic compatibility between channel material and fasteners prevents localized corrosion that could compromise joint integrity over time. Proper fastener selection and installation techniques ensure that connections maintain their strength and reliability throughout the structure's service life.

Fabrication Flexibility

The excellent formability of austenitic stainless steel channel allows for complex fabrication operations including bending, punching, and notching without compromising material properties. Cold working operations can be performed using standard metalworking equipment with appropriate tooling modifications to accommodate the material's work-hardening characteristics. This fabrication flexibility enables custom configurations and modifications that optimize structural efficiency for specific applications.

Machining operations on stainless steel channel require proper cutting speeds and tool selection but produce excellent surface finishes and dimensional accuracy. The use of sharp cutting tools and appropriate cutting fluids prevents work hardening and ensures clean cuts that maintain the material's corrosion resistance. These fabrication capabilities allow for precise fitting and assembly that enhances overall structural performance and appearance.

FAQ

How long can stainless steel channel last in outdoor applications

Properly selected and installed stainless steel channel can provide 50-100 years of service life in most outdoor environments, with some applications exceeding these timeframes. The actual service life depends on the specific grade selection, environmental conditions, and maintenance practices. Grade 316L typically offers superior longevity in coastal environments due to its enhanced chloride resistance, while grade 304 performs excellently in most inland applications with normal atmospheric exposure.

What maintenance is required for stainless steel channel structures

Stainless steel channel requires minimal maintenance, typically involving periodic cleaning with mild soap and water or pressure washing to remove accumulated dirt and debris. In industrial environments, more frequent cleaning may be necessary to prevent buildup of contaminants that could interfere with the passive layer. Regular inspection of mechanical connections and load-bearing points ensures continued structural integrity, but the stainless steel material itself requires no protective coatings or corrosion prevention treatments.

Is stainless steel channel suitable for food processing applications

Yes, stainless steel channel is excellent for food processing applications due to its non-porous surface, corrosion resistance, and ease of cleaning. Grades 304 and 316L are commonly specified for food contact applications and meet FDA requirements for food processing equipment. The smooth surface finish prevents bacterial accumulation and facilitates thorough cleaning with standard sanitization procedures, making it ideal for structural components in food processing facilities.

How does the cost of stainless steel channel compare to other structural materials

While stainless steel channel has higher initial material costs compared to carbon steel, lifecycle cost analysis typically shows significant savings over 20-year or longer service periods. The elimination of painting, coating maintenance, and premature replacement costs often results in 30-50% lower total ownership costs. For projects requiring high durability and minimal maintenance, stainless steel channel provides superior value despite the higher upfront investment.