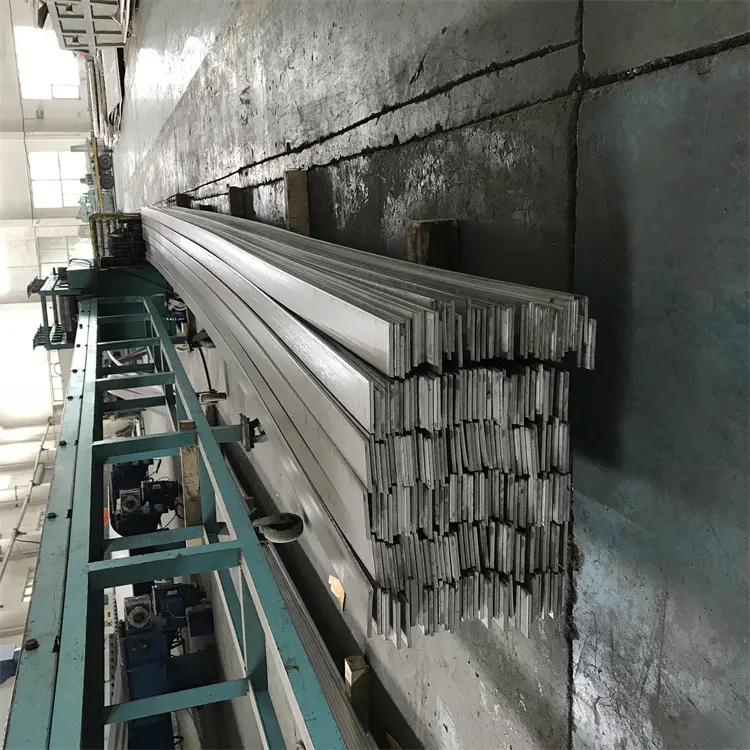

Industrial construction and manufacturing sectors increasingly rely on materials that combine exceptional durability, corrosion resistance, and structural integrity. Among these materials, stainless steel channel stands out as a versatile solution that addresses multiple engineering challenges across various applications. The unique properties of stainless steel, combined with the structural advantages of channel profiles, create an optimal building component for demanding industrial environments. Understanding the characteristics that make this material exceptional helps engineers and project managers make informed decisions for their specific requirements.

Superior Corrosion Resistance in Harsh Environments

Chemical Processing Applications

Chemical processing facilities present some of the most challenging environments for structural materials. Stainless steel channel exhibits remarkable resistance to aggressive chemicals, acids, and alkaline solutions commonly found in these settings. The chromium content in stainless steel forms a passive oxide layer that protects the underlying metal from corrosion, even when exposed to sulfuric acid, hydrochloric acid, and other corrosive substances. This protective characteristic ensures long-term structural integrity without the need for frequent replacements or extensive maintenance programs.

The uniformity of corrosion resistance across the entire profile is particularly important in chemical applications. Unlike coated materials that can suffer from localized coating failures, stainless steel channel maintains consistent protection throughout its cross-section. This property becomes critical when the material is cut, welded, or machined during installation, as the exposed surfaces retain the same corrosion-resistant properties as the original profile.

Marine and Offshore Installations

Marine environments expose structural materials to salt spray, humidity, and temperature fluctuations that rapidly degrade conventional steel components. Stainless steel channel demonstrates exceptional performance in these conditions, maintaining structural integrity for decades without significant deterioration. The material's resistance to pitting corrosion, which commonly affects other metals in chloride-rich environments, makes it an ideal choice for offshore platforms, shipbuilding, and coastal industrial facilities.

The economic benefits of using stainless steel channel in marine applications become evident over time. While the initial investment may be higher than conventional materials, the reduced maintenance requirements, extended service life, and minimal replacement needs result in significant cost savings throughout the project lifecycle. This long-term value proposition makes stainless steel channel particularly attractive for critical infrastructure projects where reliability and longevity are paramount.

Exceptional Mechanical Properties and Structural Performance

High Strength-to-Weight Ratio

The mechanical properties of stainless steel channel provide engineers with exceptional design flexibility while maintaining structural efficiency. The material offers high tensile strength, typically ranging from 500 to 800 MPa depending on the specific grade, while maintaining a relatively low density compared to other high-strength materials. This favorable strength-to-weight ratio enables the design of lighter structures without compromising load-bearing capacity or safety factors.

In applications where weight reduction is critical, such as aerospace components or mobile equipment, stainless steel channel provides an optimal solution. The channel geometry itself contributes to structural efficiency by distributing loads effectively through the web and flanges, maximizing the section modulus while minimizing material usage. This geometric advantage, combined with the inherent strength of stainless steel, creates a highly efficient structural element.

Temperature Performance and Dimensional Stability

Industrial applications often involve extreme temperature conditions that can cause significant thermal expansion, contraction, and material degradation. Stainless steel channel maintains dimensional stability across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding 800 degrees Celsius in certain grades. This thermal stability is crucial for maintaining structural alignment and preventing stress concentrations that could lead to failure.

The low thermal expansion coefficient of stainless steel channel helps minimize thermal stresses in structures subjected to temperature cycling. This property is particularly valuable in applications such as heat exchangers, furnace construction, and piping supports where thermal movement must be controlled. The material's ability to maintain its mechanical properties at both high and low temperatures ensures reliable performance across diverse operating conditions.

Manufacturing Versatility and Processing Advantages

Fabrication and Joining Capabilities

The fabrication characteristics of stainless steel channel make it highly suitable for complex manufacturing processes and custom applications. The material can be easily cut, bent, formed, and welded using conventional metalworking techniques, allowing fabricators to create specialized components and assemblies. Advanced welding techniques such as TIG, MIG, and laser welding produce high-quality joints that maintain the corrosion resistance and mechanical properties of the base material.

The work-hardening characteristics of stainless steel channel can be advantageous in certain applications where increased strength is desired through cold forming processes. However, this property also requires careful consideration during fabrication to prevent excessive hardening that could affect formability. Proper annealing procedures can restore the material's original properties when necessary, providing additional flexibility in manufacturing processes.

Surface Finishing Options

Stainless steel channel is available in various surface finishes that can be selected based on specific application requirements. The standard mill finish provides excellent corrosion resistance and is suitable for most industrial applications where appearance is not a primary concern. For applications requiring enhanced aesthetics or improved cleanability, polished finishes ranging from 240 grit to mirror finish are available.

Specialized surface treatments can further enhance the performance characteristics of stainless steel channel. Passivation treatments optimize the passive layer formation, maximizing corrosion resistance in critical applications. Electropolishing removes surface imperfections and creates an ultra-smooth finish that reduces particle adhesion and simplifies cleaning procedures, making it ideal for pharmaceutical and food processing applications.

Grade Selection and Application-Specific Benefits

Austenitic Grades for General Applications

The most commonly used stainless steel channel grades belong to the austenitic family, particularly 304 and 316 series alloys. These grades offer excellent corrosion resistance, good formability, and non-magnetic properties that make them suitable for a wide range of industrial applications. The 304 grade provides cost-effective performance for general construction, architectural applications, and mild corrosive environments.

The 316 grade contains molybdenum additions that significantly enhance corrosion resistance, particularly in chloride-containing environments. This makes 316 stainless steel channel the preferred choice for marine applications, chemical processing equipment, and medical device manufacturing. The superior pitting and crevice corrosion resistance of 316 grade justifies the additional cost in critical applications where failure could result in significant consequences.

Specialized Grades for Demanding Conditions

For applications involving extreme conditions, specialized stainless steel grades offer enhanced performance characteristics. The 321 grade contains titanium stabilization that prevents carbide precipitation during welding, making it ideal for high-temperature applications and welded structures. This stabilization ensures that the heat-affected zone maintains corrosion resistance equivalent to the base material.

Duplex stainless steel grades combine the benefits of austenitic and ferritic structures, providing higher strength and improved stress corrosion cracking resistance. These grades are particularly valuable in oil and gas applications, desalination plants, and other environments where both mechanical strength and corrosion resistance are critical. The selection of the appropriate grade depends on specific environmental conditions, mechanical requirements, and economic considerations.

Economic Considerations and Lifecycle Value

Initial Investment vs Long-term Savings

While stainless steel channel typically requires a higher initial investment compared to carbon steel alternatives, the total cost of ownership often favors stainless steel in industrial applications. The elimination of protective coatings, reduced maintenance requirements, and extended service life contribute to significant cost savings over the project lifecycle. These economic benefits become more pronounced in corrosive environments where conventional materials would require frequent replacement or intensive maintenance.

The reduced downtime associated with stainless steel channel installations provides additional economic value in industrial settings where production interruptions are costly. The reliability and longevity of stainless steel components minimize unplanned maintenance events and extend the intervals between scheduled maintenance activities. This operational advantage often justifies the higher material cost through improved productivity and reduced operational expenses.

Sustainability and Environmental Impact

Stainless steel channel contributes to sustainable construction practices through its exceptional durability and complete recyclability. The extended service life reduces the frequency of replacement and associated environmental impacts from manufacturing, transportation, and disposal activities. At the end of its service life, stainless steel channel can be recycled without loss of properties, contributing to circular economy principles.

The energy efficiency of structures utilizing stainless steel channel also contributes to environmental benefits. The material's thermal properties and durability help maintain building envelope integrity over extended periods, reducing energy consumption for heating and cooling. These sustainability advantages align with modern industrial practices focused on environmental responsibility and resource conservation.

FAQ

What are the main advantages of using stainless steel channel in industrial construction

Stainless steel channel offers superior corrosion resistance, high strength-to-weight ratio, excellent temperature performance, and long-term durability. These properties make it ideal for harsh industrial environments where conventional materials would fail prematurely. The material requires minimal maintenance and provides reliable performance over extended service periods, resulting in lower total cost of ownership despite higher initial investment.

How do I select the appropriate stainless steel grade for my application

Grade selection depends on environmental conditions, mechanical requirements, and economic considerations. For general applications with mild corrosive conditions, 304 grade provides cost-effective performance. For marine environments or chemical processing, 316 grade offers enhanced corrosion resistance. Specialized applications may require duplex grades or stabilized versions like 321 for high-temperature service. Consulting with materials engineers helps ensure optimal grade selection for specific requirements.

Can stainless steel channel be welded and fabricated like conventional steel

Yes, stainless steel channel can be welded and fabricated using conventional techniques with some modifications to procedures and filler materials. TIG and MIG welding produce high-quality joints that maintain corrosion resistance. Proper heat input control and post-weld treatments may be necessary to preserve material properties. The material's work-hardening characteristics should be considered during forming operations to prevent excessive hardening.

Is stainless steel channel cost-effective compared to coated carbon steel alternatives

While stainless steel channel has higher initial costs, it often provides better long-term value in corrosive environments. The elimination of coating systems, reduced maintenance requirements, and extended service life result in lower total cost of ownership. In applications where reliability is critical or access for maintenance is limited, stainless steel channel typically offers superior economic value over the project lifecycle.

Table of Contents

- Superior Corrosion Resistance in Harsh Environments

- Exceptional Mechanical Properties and Structural Performance

- Manufacturing Versatility and Processing Advantages

- Grade Selection and Application-Specific Benefits

- Economic Considerations and Lifecycle Value

-

FAQ

- What are the main advantages of using stainless steel channel in industrial construction

- How do I select the appropriate stainless steel grade for my application

- Can stainless steel channel be welded and fabricated like conventional steel

- Is stainless steel channel cost-effective compared to coated carbon steel alternatives