Excellence in Stainless Steel Manufacturing: Setting Industry Standards

In the dynamic world of metallurgy and industrial manufacturing, a distinguished 321 SS plate manufacturer plays a pivotal role in shaping the quality and reliability of countless applications. From aerospace components to chemical processing equipment, the expertise of these manufacturers determines the success of critical projects worldwide. The manufacturing of 321 stainless steel plates requires exceptional precision, advanced technology, and unwavering commitment to quality standards that set leading producers apart from the competition.

Core Manufacturing Capabilities and Technology

State-of-the-Art Production Facilities

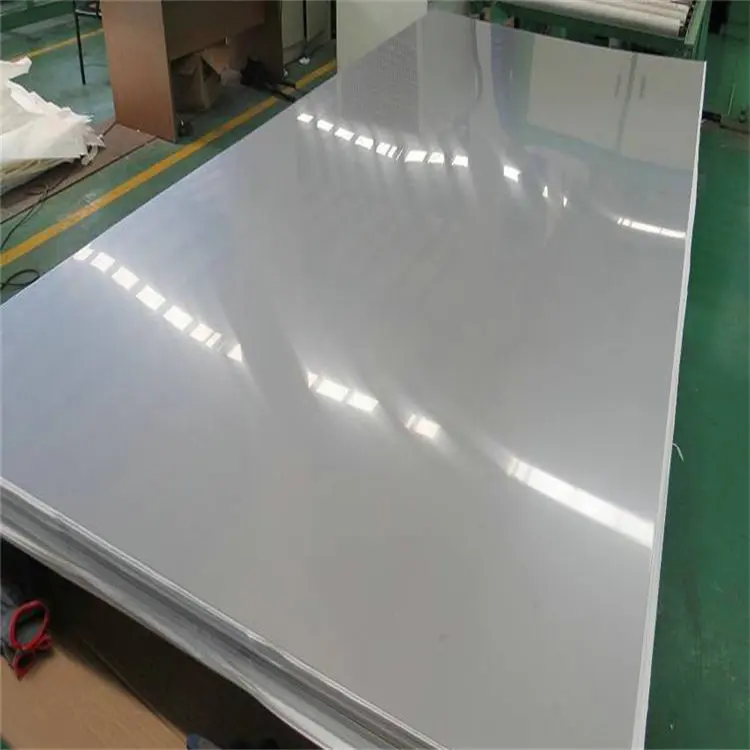

A premier 321 SS plate manufacturer invests heavily in cutting-edge production facilities that ensure consistent quality and precise specifications. Modern manufacturing plants feature advanced rolling mills, heat treatment furnaces, and automated quality control systems. These sophisticated facilities enable manufacturers to produce plates with superior surface finish, exact dimensional tolerance, and optimal mechanical properties. The integration of smart manufacturing technologies and Industry 4.0 principles further enhances production efficiency and product reliability.

Quality Control and Testing Protocols

Excellence in manufacturing is maintained through rigorous quality control processes. Leading manufacturers implement comprehensive testing protocols at every production stage, from raw material verification to final product inspection. Advanced testing equipment, including spectrometers, ultrasonic testing devices, and mechanical testing apparatus, ensures that each plate meets or exceeds industry standards. Regular calibration and maintenance of testing equipment guarantee accurate and reliable results.

Material Expertise and Innovation

Superior Grade Selection and Processing

Distinguished manufacturers demonstrate exceptional expertise in material selection and processing techniques. They maintain strict control over the chemical composition of 321 stainless steel, ensuring the perfect balance of chromium, nickel, and titanium stabilization. This expertise extends to understanding how various processing parameters affect the final product properties, enabling them to optimize manufacturing processes for specific applications and customer requirements.

Research and Development Initiatives

Leading manufacturers invest significantly in research and development to advance material science and processing technologies. These initiatives focus on improving product performance, developing new grades, and enhancing manufacturing efficiency. Collaboration with research institutions and industry partners facilitates innovation in areas such as surface treatment technologies, heat treatment processes, and sustainable manufacturing practices.

Customer Service and Technical Support

Comprehensive Technical Assistance

Outstanding 321 SS plate manufacturers provide extensive technical support to customers throughout their projects. Expert metallurgists and engineers offer guidance on material selection, design considerations, and processing recommendations. This technical expertise helps customers optimize their applications and avoid potential issues during fabrication or service life. Regular technical consultations and documentation support ensure customers make informed decisions about their material requirements.

Customization and Flexibility

The ability to accommodate custom specifications and unique requirements sets premier manufacturers apart. They maintain flexible production schedules and capabilities to handle varying order sizes and specifications. This adaptability extends to providing specialized surface finishes, non-standard dimensions, and specific mechanical properties tailored to customer applications. The willingness to develop custom solutions demonstrates their commitment to customer satisfaction.

Environmental Responsibility and Sustainability

Sustainable Manufacturing Practices

Leading 321 SS plate manufacturers implement environmentally responsible practices throughout their operations. This includes energy-efficient production processes, waste reduction initiatives, and recycling programs. Advanced filtration systems and emission control technologies minimize environmental impact while maintaining high production standards. These manufacturers often exceed regulatory requirements and set new benchmarks for sustainable manufacturing in the industry.

Certification and Compliance

Environmental certifications and compliance with international standards demonstrate a manufacturer's commitment to sustainability. They maintain ISO 14001 certification and participate in environmental management programs. Regular audits and continuous improvement initiatives ensure their operations meet evolving environmental regulations while maintaining production efficiency and product quality.

Global Market Presence and Reliability

International Distribution Network

Successful manufacturers maintain extensive global distribution networks to serve customers worldwide. Strategic partnerships with logistics providers and warehousing facilities ensure efficient delivery and inventory management. Their international presence enables them to understand and adapt to regional market requirements while providing consistent service quality across different locations.

Industry Recognition and Track Record

Years of successful operation and industry recognition build trust in a manufacturer's capabilities. Their track record of delivering high-quality products, meeting delivery schedules, and providing excellent service establishes their reputation as reliable partners. Industry awards, certifications, and customer testimonials further validate their position as leaders in stainless steel manufacturing.

Frequently Asked Questions

What certifications should a quality 321 SS plate manufacturer possess?

A reputable manufacturer should hold ISO 9001:2015 quality management certification, ISO 14001 environmental management certification, and industry-specific certifications such as ASME, PED, and DNV GL. These certifications ensure compliance with international quality standards and industry requirements.

How do manufacturers ensure consistent quality across different production batches?

Quality consistency is maintained through strict process control, regular equipment calibration, comprehensive testing protocols, and detailed documentation of manufacturing parameters. Advanced quality management systems track and analyze production data to identify and address any variations promptly.

What should customers look for when selecting a 321 SS plate manufacturer?

Customers should evaluate the manufacturer's technical capabilities, quality certifications, production capacity, customer service record, and financial stability. Additionally, consider their experience with similar applications, ability to meet specific requirements, and commitment to long-term partnership.

Table of Contents

- Excellence in Stainless Steel Manufacturing: Setting Industry Standards

- Core Manufacturing Capabilities and Technology

- Material Expertise and Innovation

- Customer Service and Technical Support

- Environmental Responsibility and Sustainability

- Global Market Presence and Reliability

- Frequently Asked Questions