Understanding the Impact of Quality Stainless Steel Manufacturing on Industrial Success

In today's demanding industrial landscape, the choice of a 321 SS plate manufacturer can make or break project outcomes. High-quality stainless steel grade 321 has become increasingly vital across various sectors, from aerospace to chemical processing, where material integrity directly influences operational efficiency and safety standards. As industries evolve and specifications become more stringent, partnering with a reputable 321 SS plate manufacturer has never been more crucial.

The significance of selecting the right manufacturing partner extends far beyond mere material procurement. It encompasses quality assurance, technical support, delivery reliability, and ultimately, the success of your entire project. When stakeholders understand the full spectrum of benefits that come with choosing an experienced 321 SS plate manufacturer, they can make informed decisions that positively impact their bottom line.

Essential Characteristics of Premium Stainless Steel Manufacturing

Advanced Manufacturing Processes

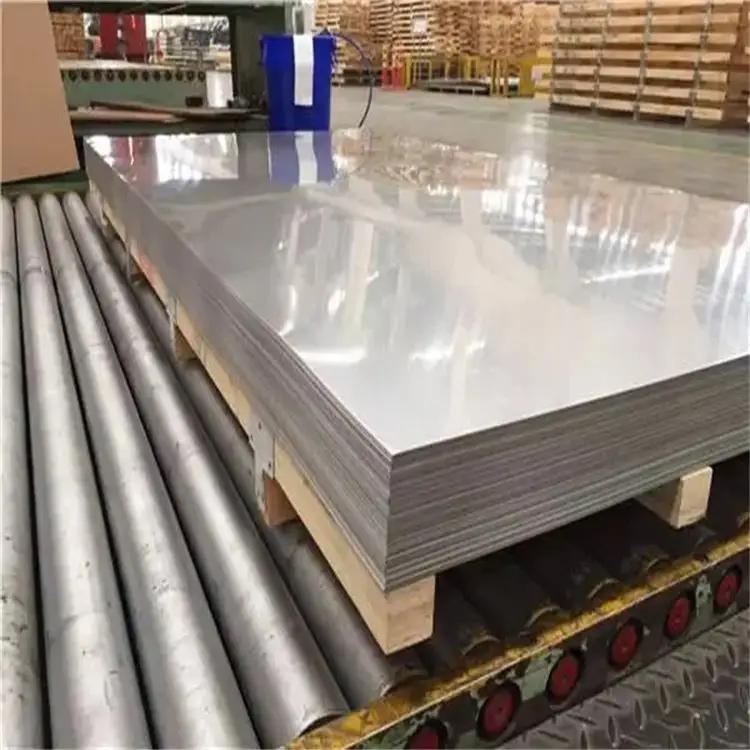

Leading 321 SS plate manufacturer facilities employ state-of-the-art technology and precise control mechanisms throughout the production process. From initial melting to final finishing, each step is meticulously monitored to ensure consistent quality. Advanced manufacturing processes include controlled atmosphere melting, precise temperature regulation during hot rolling, and sophisticated heat treatment procedures that optimize the material's properties.

These manufacturers invest heavily in modern equipment and regularly upgrade their facilities to maintain competitive advantages. The implementation of automated systems and real-time quality monitoring helps eliminate human error and ensures every plate meets exact specifications.

Quality Control Standards

Premium 321 SS plate manufacturer operations maintain rigorous quality control protocols that exceed industry standards. This includes comprehensive material testing at multiple production stages, from chemical composition analysis to mechanical property verification. Regular calibration of testing equipment and documented quality procedures ensure consistency across all production batches.

Third-party certifications and compliance with international standards provide additional assurance of manufacturing excellence. These manufacturers typically maintain ISO certifications and industry-specific qualifications that demonstrate their commitment to quality and continuous improvement.

Maximizing Project Performance Through Material Excellence

Technical Support and Expertise

A distinguished 321 SS plate manufacturer offers more than just products; they provide valuable technical expertise that can enhance project outcomes. Their engineering teams can assist with material selection, application-specific recommendations, and troubleshooting support. This collaborative approach helps clients optimize their material usage and avoid potential issues during fabrication or installation.

Access to specialized knowledge and experience can significantly reduce project planning time and minimize costly mistakes. Whether dealing with complex specifications or challenging applications, having expert support from your 321 SS plate manufacturer proves invaluable.

Supply Chain Efficiency

Reliable manufacturers maintain robust inventory management systems and strategic partnerships throughout the supply chain. This enables them to offer competitive lead times and flexible delivery options that align with project schedules. By working with a well-established 321 SS plate manufacturer, projects benefit from predictable material availability and reduced logistics complications.

The ability to respond quickly to urgent requirements and maintain consistent supply during market fluctuations provides a significant advantage. This reliability translates directly into improved project timelines and reduced storage costs.

Cost-Effectiveness and Long-Term Value

Initial Investment versus Lifetime Benefits

While premium 321 SS plate manufacturer products may command higher initial prices, the long-term value proposition becomes evident through superior performance and reduced maintenance requirements. High-quality stainless steel plates offer extended service life, better corrosion resistance, and improved mechanical properties that justify the investment.

Consider the costs associated with material failure, maintenance downtime, and replacement requirements. Quality materials from reputable manufacturers help minimize these expenses over the project lifecycle, resulting in better overall cost-effectiveness.

Sustainability and Environmental Considerations

Modern 321 SS plate manufacturer operations increasingly focus on sustainable practices and environmental responsibility. This includes energy-efficient production processes, responsible resource management, and recyclable products. Working with environmentally conscious manufacturers aligns with corporate sustainability goals and regulatory requirements.

The durability and recyclability of quality stainless steel contribute to reduced environmental impact over time. These considerations become increasingly important as industries face growing pressure to adopt sustainable practices.

Frequently Asked Questions

What certifications should I look for in a 321 SS plate manufacturer?

Look for manufacturers with ISO 9001 certification, industry-specific qualifications such as ASME certification, and compliance with relevant ASTM standards. Additional certifications like ISO 14001 for environmental management demonstrate comprehensive quality commitment.

How can I verify the quality of 321 SS plates before purchase?

Request material test certificates, review the manufacturer's quality control procedures, and consider conducting site visits or third-party inspections. Reputable manufacturers will readily provide documentation and welcome quality audits.

What lead times can I expect from a reliable manufacturer?

Standard lead times typically range from 4-12 weeks, depending on specifications and quantity. However, established manufacturers often maintain stock items for faster delivery and can accommodate rush orders when needed through efficient production planning.