အလွယ်တကူ အချက်အလက်:

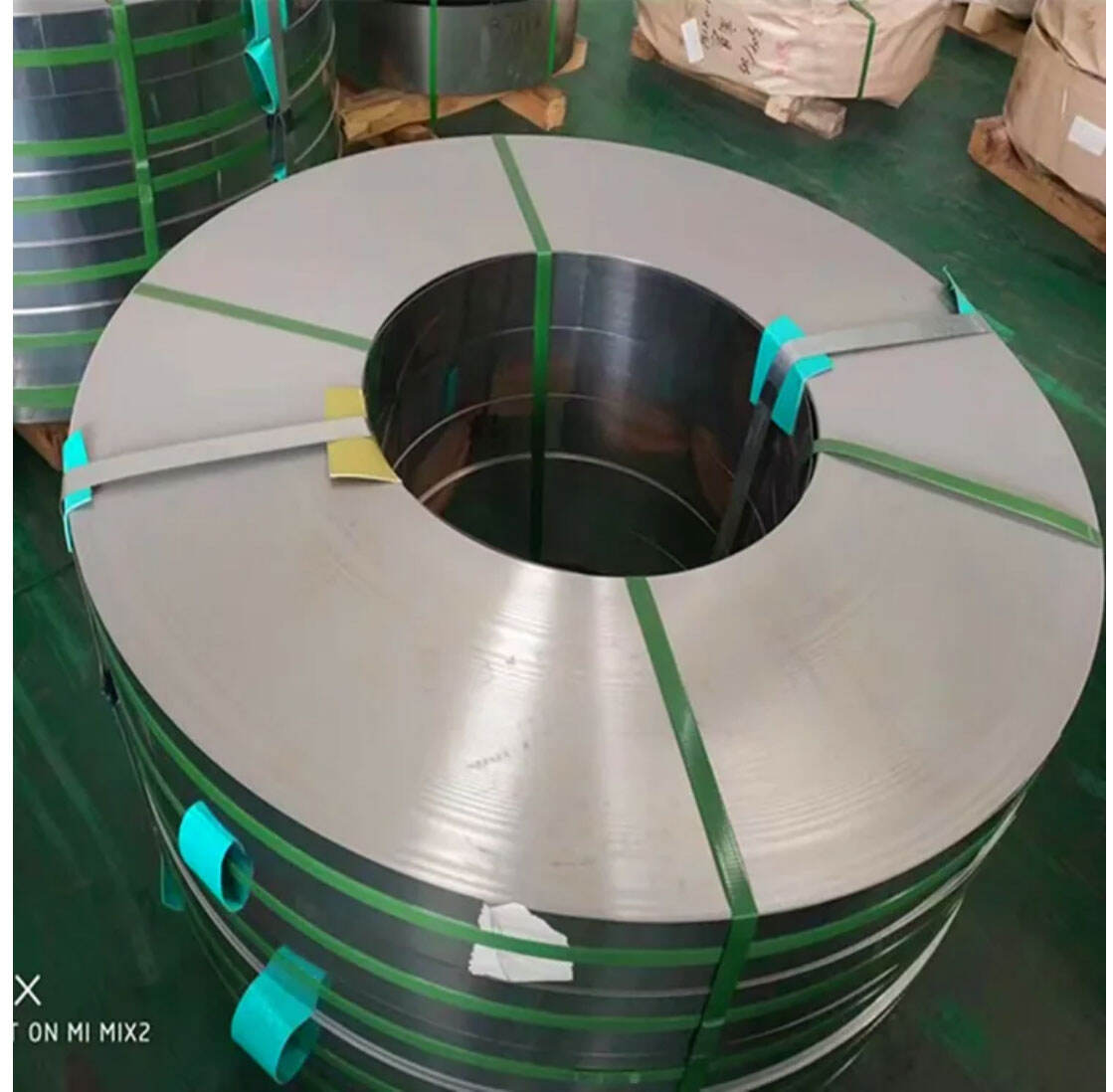

1, မျက်နှာရေးဆောင်ခြင်း ဟာလို၊ လှင့်မှု အမှတ်တံဆိပ်၊ ရဲလေးမှတ်များ မရှိ

2, မြစ်မှုကြီးမားသည်၊ လျော်ချင်းမှု မရှိ

3, ကောင်းမွန်သော ပျှမ်းမျှခြင်း၊ ကောင်းမွန်သော ထူးခြောက်ခြင်း

4, မည်သည့် ပိုင်းခြားမှုမဆို လွယ်ကူသည်၊ လျှော့ချထားသော ဘားများ ပြင်းပြီးသည်

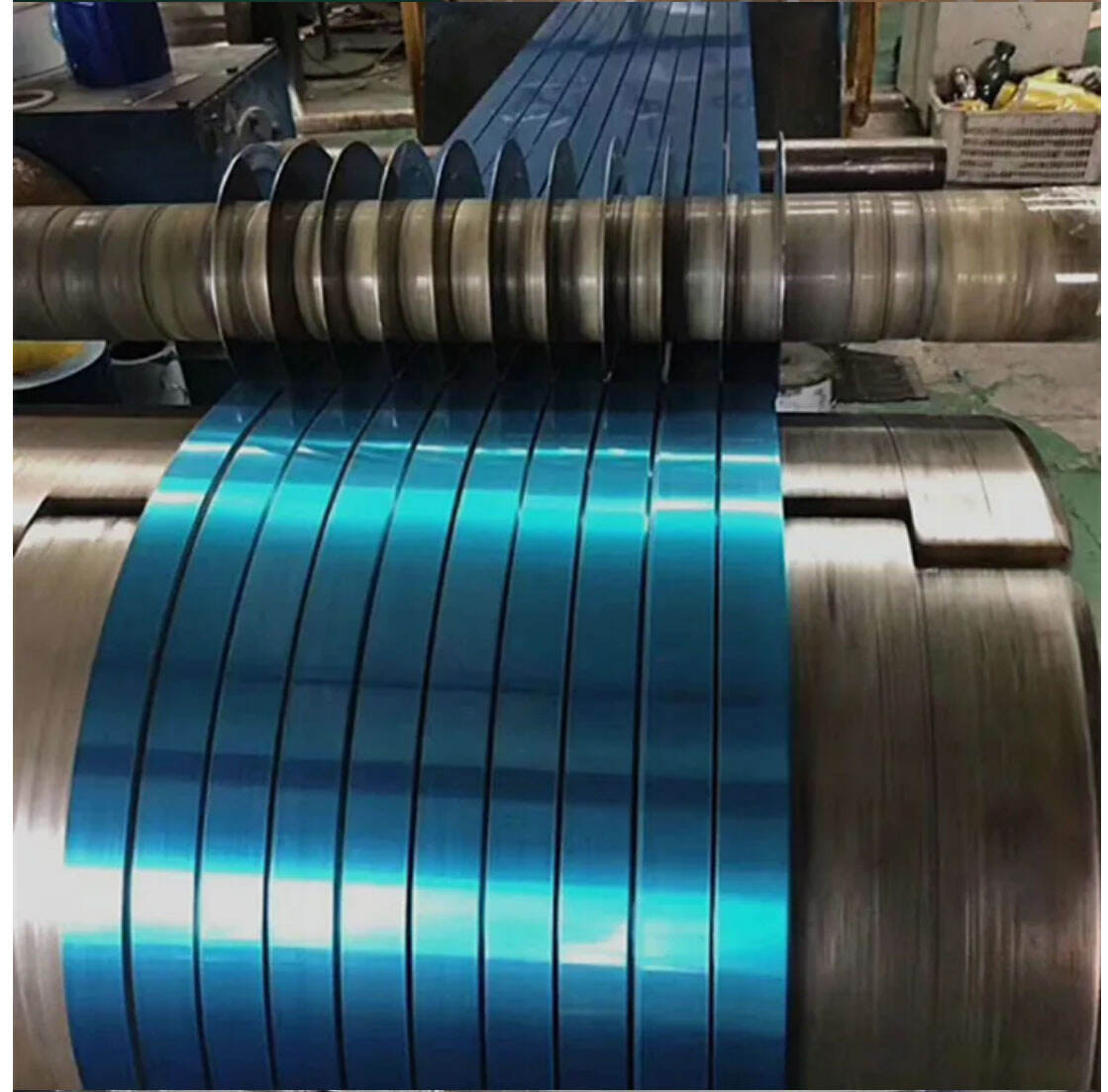

အပူချိန်နှောင့် လုပ်ထားသော သံမဏိမော်လီကျူး

ကိုင်တွယ်မဟုတ်သော လှောင်မှုအစိမ်းဆိပ်/ကိုင်တွယ်မဟုတ်သော လှောင်မှုကို အပူချိန်တွင် လှောင်မှုရဲ့ အစိမ်းဆိပ်အဖြစ် အသုံးပြုသည်။ စုစုပေါင်း အလေးချိန် <0.1mm~3mm>၊ အကျယ် <100mm~2000mm>။

အပူချိန်နှောင့် လုပ်ထားသော လောင်စိန်ဆိုင်း/ကိုင်းမှာ ပြင်ဆင်သော မျက်နှာ၊ ပြေးမှု၊ အရွယ်အစားများအတွင်း မှန်ကန်မှုမြင့်၊ နှင့် ကောင်းသော ကိရိယာများ၏ ဂုဏ်သိက္ခာများကို ပါဝင်သည်။ ထုတ်ကုန်များ ကိုယ်တိုင်မျဉ်းများအဖြစ် ဝင်ရောက်ပြီး ကိုယ်တိုင်ချိုးထားသော လောင်းရောင်းမျဉ်းများအဖြစ် ပြုလုပ်နိုင်သည်။

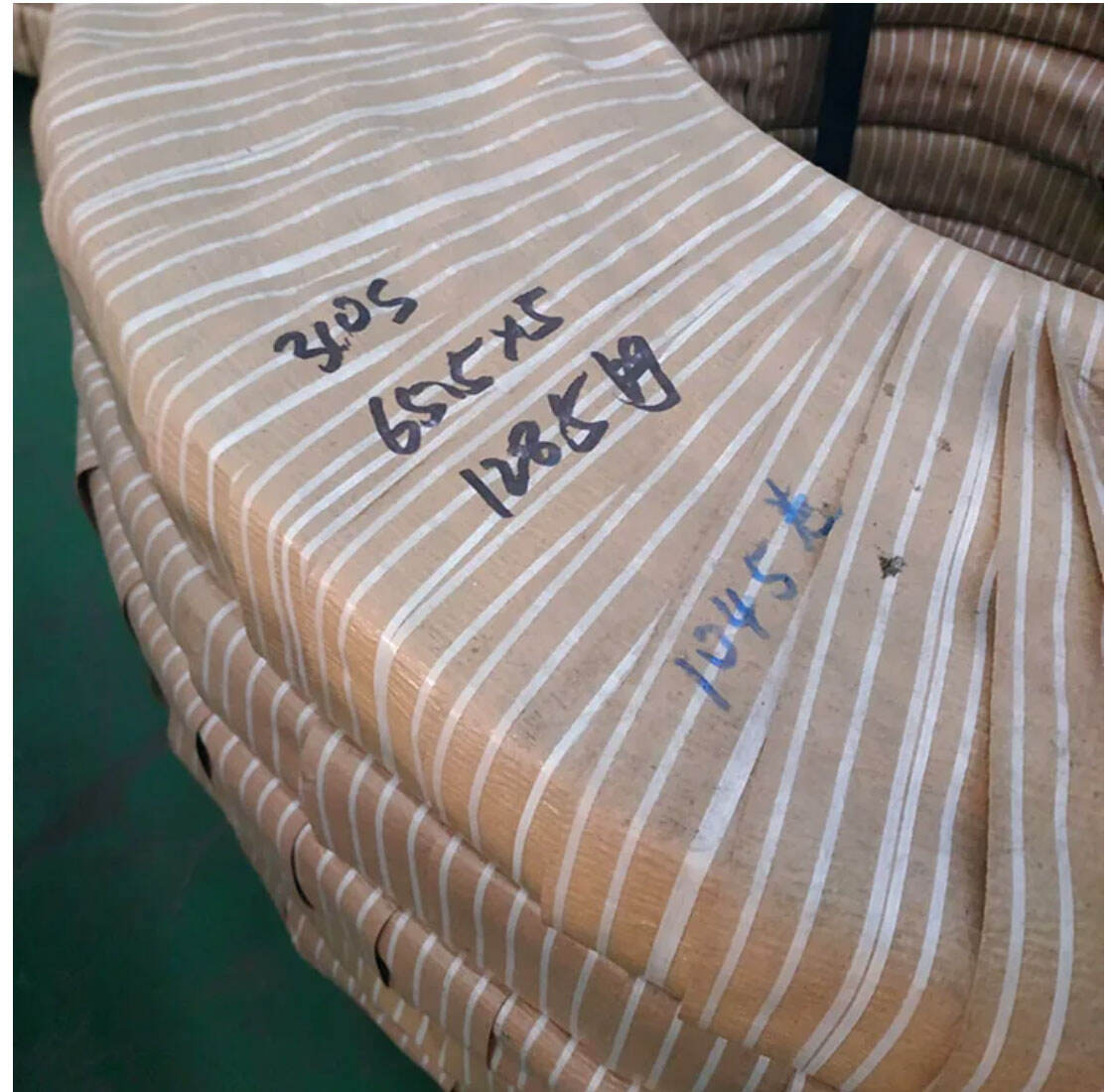

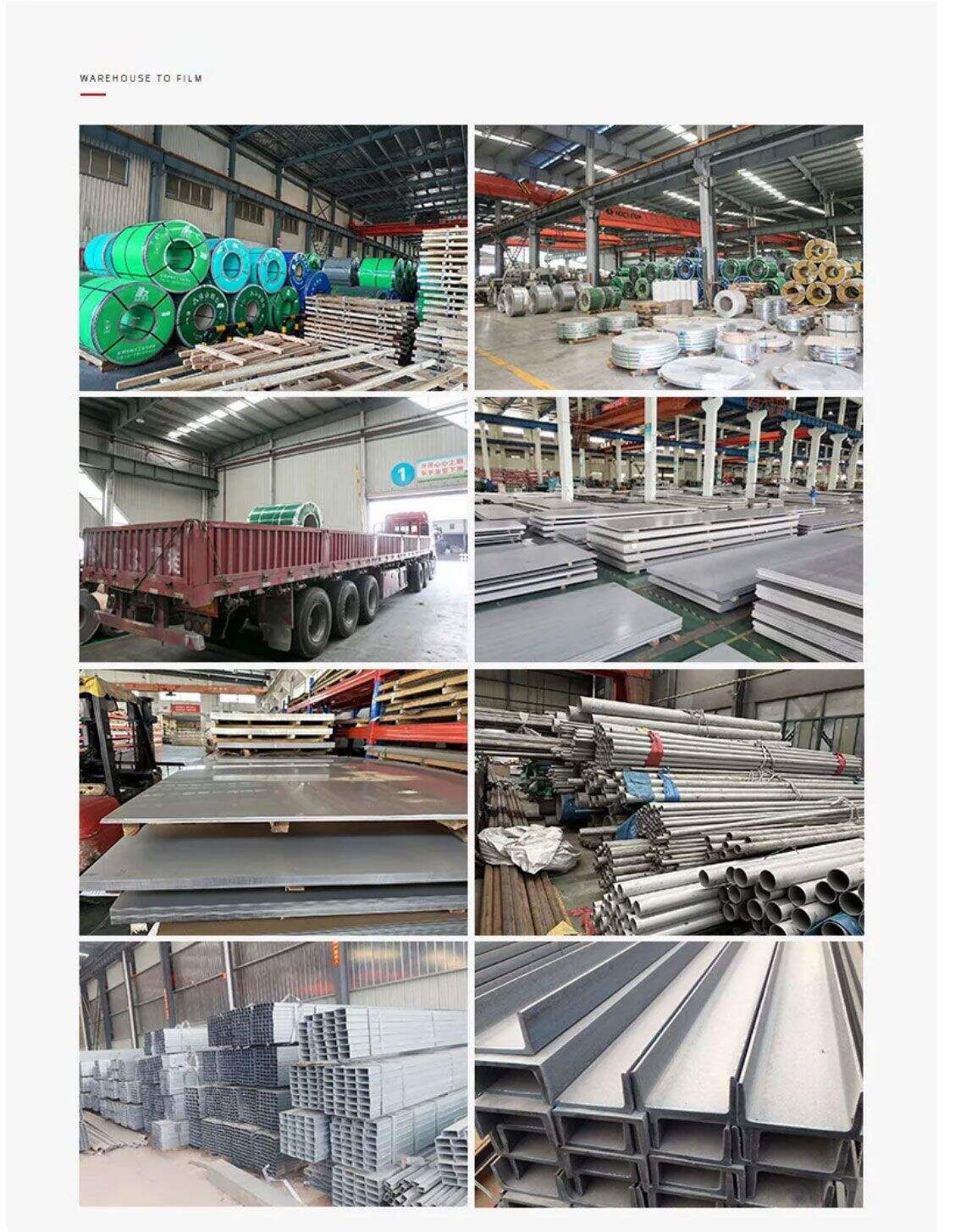

အပူချိန်တွင် ဆိုဒ်ထုတ်ထားသော ကြေးသီးစား

အလေးချိန် ၁.၈၀mm မှ ၆.၀၀mm အထိ နှင့် အကျယ် ၅၀mm မှ ၁၂၀၀mm အထိရှိ ပြင်ထုတ်ခြင်းဖြင့် ရရှိသည့် ကျန်းမာလောဟာအိတ်စား。

ပြင်ထုတ်ခြင်းဖြင့် ရရှိသည့် အိတ်စားများ/ပြားများသည် အဆင်မြင်မှုနည်း၊ အလုပ်လုပ်ရေးလွယ်ကူမှု၊ နှင့် ကောင်းသော ပြားဝင်မှုရှိသည်။

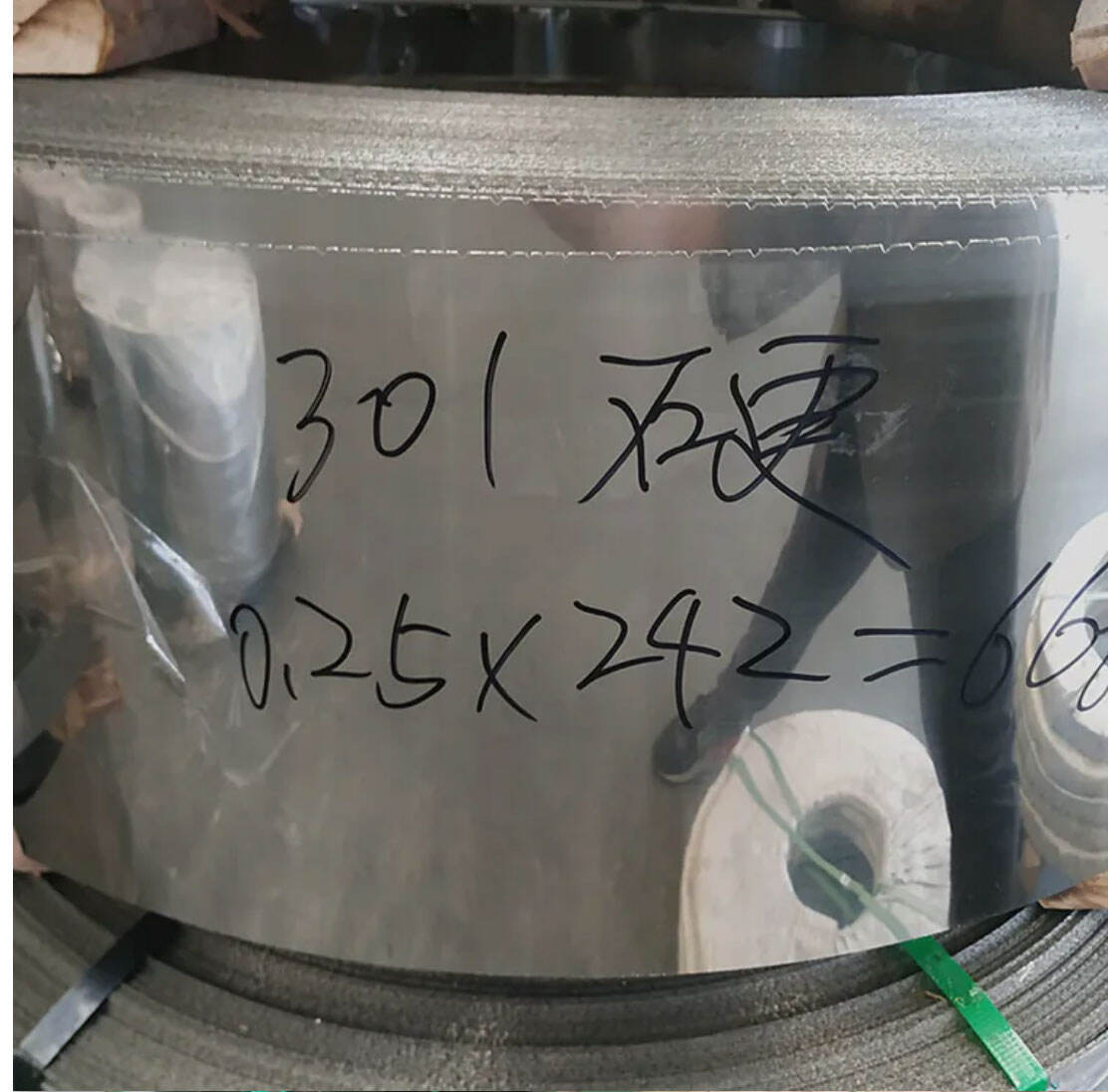

အပူချိန်တွင် ဆိုဒ်ထုတ်ထားသော နှင့် အပူချိန်တွင် ဆိုဒ်ထုတ်ထားသော ကြေးသီးစားများ ကြားရှိသော ခြားနားချက်များ

အေးထုတ်ခြင်းဖြင့် ရရှိသည့် လောဟာအိတ်စားများသည် ကောင်းသော အစိုးရမှုနှင့် ပြားဝင်မှုအချိုးအစားရှိသည်၊ နှင့် ပြင်ထုတ်ခြင်းဖြင့် ရရှိသည့် လောဟာအိတ်စားများသည် ကောင်းသော ပြားဝင်မှုနှင့် အဆင်မြင်မှုရှိသည်။

အောက်ခံပြင်သည်၏ ပြင်ဆင်မှု၊ အပြင်စောင်းနှင့် အရွယ်အစားအတည်မှာ ဖိုးရဲ့ လျှော့ချထားသော လေးမျဉ်းထက် ကောင်းမွန်သည်။

လျှော့ချထားသော လေးမျဉ်း၏ ပြင်အလေ့သည် အလွန်ပြီးသော်လည်း ဖိုးရဲ့ လေးမျဉ်း၏ ပြင်အလေ့သည် ပိုမိုကြီးမားသည်။