Дундаж мэдээлэл:

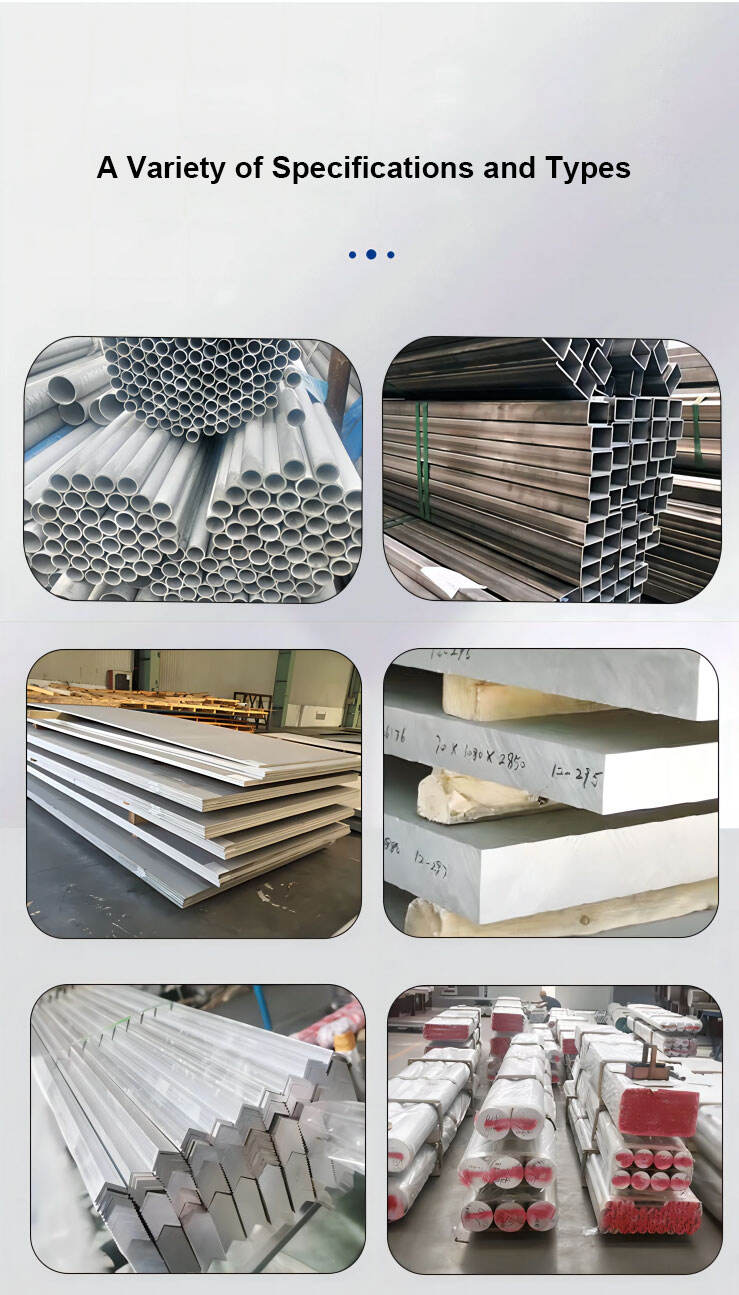

1, Өргөн: дөрвөлжин бар, квадрат бар, гурвалжин бар, тэнгэр бар, гэх мэт.

2, Хажуу урт / гаригийн урт: Дөрвөлжин барын хэрэгслүүд нь ерөнхийд Φ1мм~Φ300мм, квадрат бар, гурвалжин барын гаригийн урт нь 3мм~100мм.

3, Урт: Ерөнхийдээ зөөлөн барын урт нь 1м~6м ба их эсвэл бага урттай хамгийн их урт.

Цагаан толгойн дөрвөн газар нь урт материалын төрөл бөгөөд эргүүлэх баруун төрөл болох мэт, энэ нь эргүүлэх хэсгийн дөрвөн урт материал юм. Үүнийг 4 метр урттай байдаг. Энэ нь хоцорсон цагаан дөрвөн гэж нэрлэгдэнэ. Хоцорсон дөрвөн гэдэг нь зөөлөн хөршөөрөөр шилжүүлсэн бөгөөд цагаан толгойн хөрш нь хоцорсон байдаг. Хоцорсоогүй дөрвөн гэдэг нь хөрш нь хар өндөр байдаг.

Танилцуулга

Цагаан толгойн дөрвөн гэдэг нь дөрвөн хэсгийн булангуудтай байдалтай бөгөөд урт баруун материал юм. Тодорхойлолтууд нь диаметрийн мм-ээр илэрхийлэгдэнэ. Жишээлбэл "50" нь 50мм диаметртэй цагаан толгойн дөрвөн гэсэн үг юм.

Хамгийн их ашиглагддаг материалууд нь 301, 304, 303, 316, 316L, 304L, 321, 2520, 201, 202 гэх мэт байна. Норм хэмжээнүүд диаметрээр илэрхийлэгддэг, жишээлбэл "50" нь 50мм диаметртэй дөрвөлжин төмөр гэсэн үг юм. Дөрвөлжин төмөр нь улаан чимэглэлийн, шарахын, цагаан чимэглэлийн гурван ангид хуваагддаг. Улаан чимэглэлийн дөрвөлжин төмөрний норм хэмжээ нь 5.5-250мм байна.

Арслан төмөрний дөрвөлжин төмөр нь ихээхэн зориулалтаар ашигладаг бол эзэн санаанд нь хамгаалалтын үйлдвэр, бусад судалгааны тоног төхөөрөмж, шип хийц, хими, машин, медицин, номын үйлдвэр, электрийн үйлдвэр, энергийн үйлдвэр, далайн хоолны үйлдвэр, барилгын засвар, далайн усны тоног төхөөрөмж, химийн, шаргал, хар, муу, хөрш хийц, зураг, хоолны үйлдвэр, далайн байгууламж, шугам, CD төмөр, шүүгээр, шүүгэн.

Төрөл ба үсгийн тодорхойлолт

Үндсэн бий болгох аргаар stainlesst нисэх төмрөөс үүсгэсэн тойрог төмрөөс хамаарахдаа их, дулаанд хийгдсэн, зогсооны дагуу гурван хувьд хувааж болно. Дулааны дагуу stainlesst нисэх төмрөөс үүсгэсэн тойрог төмрөөсийн стандарт нь 5.5-250 мм байна. Эдгээр утгуудын дотор 5.5-25 мм-ийн бага stainlesst нисэх төмрөөс үүсгэсэн тойрог төмрөөс нь эерэг шугамтай байдлын хувьд суулгана. Энэ нь төмрөөс үүсгэсэн цонх, болтын төрлүүдэд ашигладаг. 25 мм-аас их stainlesst нисэх төмрөөс үүсгэсэн тойрог төмрөөс нь механикчлалын хэсгүүдийг үйлдвэрлэхэд эсвэл хоолой төмрөөс үүсгэх загварын материал болох ёстой.

Удирдамжийн хувьд

1.310S stainless steel round steel

Онцлог: 310S stainless steel нь австенитик хром-никельтэй stainlesst нисэх төмрөөс үүсгэсэн тойрог төмрөөс бөгөөд хамгаалалттай, коррозийн үр дүнтэй. Хром ба никельний хэмжээний олон тооны улмаас 310S нь илүү сайн криптийн чадвартай, их температурт ажиллах боломжтой бөгөөд их температуртай үеэрээ сайн ажилладаг.

2.316L stainless steel round steel

Онцлог шинж чанарууд:

1) Халуунд давхцсан байдал нь бүтээгдэхүүнүүд зүрхлэх өнгөтэй бөгөөд зүрхлэлтэй;

2) Мо-г нэмсэн тул, ихэвчлэн цагаан шарахын хамгаалалт нь сайн байдаг;

3) Их хэмжээний халуун давхаргын чадвар;

4) Амжилттай ажиллах хүч (процессийн дараа магнетикийн хувьд бага)

5) Шугаман бусад халдварын үед магнит биш;

3.316 нислэг төмөртэй дөрвөлжин гурвалжны төмөр

Тодорхойлолт: 316 нислэг төмөр нь 304-ийн дараа хамгийн их ашиглагддаг төмөр юм. Энэ нь эцсийн байгууллагуудад болон хирургийн тоног төхөөрөмжид ашигладаг. Mo-г нэмсэн тул түүний цусны үндэслэлийн үр чадвар, сарнигчийн үр чадвар болон урт ойролцооны үүсвэр нь ихэнхдээ сайн байдаг. Тухайн нөхцөлд ашиглах боломжтой; зөвхөн шинжилгээний үр дүнтэй (магнит биш).

4.321 нислэг төмөртэй дөрвөлжин гурвалжны төмөр

Тодорхойлолт: 304 төмөрт Ti элемент нэмэгдсэн тул хавтаасын хооронд цусны үр чадварыг буцааж авах боломжтой, 430 ℃-900 ℃ хүснэгтэнд ашигладаг. Титанийг нэмсэн тул материалын хавтаасын цусны үр чадвар багассан боловч өөрөөр хэлбэл 304-тэй ижил үйлдлүүдтэй.

5.304L нүүрсний төмөр бөмбөгтэй дөрвөлжин төмөр

Үзүүлэлт: 304L нүүрсний төмөр бөмбөгтэй дөрвөлжин төмөр нь 304 нүүрсний төмөртэй холбоотой, уур агаарын тохиргооны үед ашиглагддаг нэмэлт орцтой хувилбар юм. Нэмэлт орцыг бууруулсан нь ууламжлалтай зониуд дахь карбидын чимэглэлийг багасгаж, нягтралын коррозийг (ууламжлалтай эргэлзээ) ямар нэгэн орчинд нь шинжлэх боломжтой.

6.304 нүүрсний төмөр бөмбөгтэй дөрвөлжин төмөр

Онцлог: 304 нүүрсний төмөр нь хамгийн их ашигладаг кром-никельтэй нүүрсний төмөр юм, эерэг коррозитай, үүрэгтэй, цагаан уур агаартай, зөвхөн амьдралын уур агаар эсвэл их л бусад сорилтын газар байдаг. Коррозитай байхыг буцаахын тулд цаг агаарынхаа цагдаагүйгээр цэвэрлэх шаардлагатай.

Халуун

Хавтгай дээр багтсан хоолойн цэвэрлэгчид нь төмөр шаргалын коррозийг нөөцлөх боломжтой. Хоолойн цэвэрлэгч багтсан үед, тэдгээрийн дэвсгэр дээр илүү хамгийн усны эмзэг байдаг бол хорионгийн ионууд агуулахад тусалж, оюун зөвшөөрөхийг хязгаарлаж, пассивацын эмзэгийг хасах боломжтой. Мөн энэ дисперсион хүрээнд байрладаг зонгогчдын дарааллын хооронд холбогдох хүрээ нь точин яслагын үүсэлтээс хамаарах болно.

шаргалтай шийдвэрлэх

(1) хоолойлох (пилли) гэж: энд мөн ихэвчлэн микроскопик шил уурхайн дагуу шаргалын харанхуй эмзэгтэй холбоотой.

(2) Химийн арга: 1 төрлийн загасгүй цэвэрлэх, пассивчлах буц идэвхжүүлэх боломжтой ороомиог нэмсэн зочид хамгааллагатай цэвэрлэх эмчилгээний ашиглан шингээн цэвэрлэх. Энэ нь нисэх санаагаар нисэх санаагаар хангахыг зорьсон. Цэвэрлэгчийн үеэрээ тодорхой хувьд дулаан байдлыг үзүүлдэг. Энэ нь их, том бутлууртай бараанд маш сайн хэрэглэгдэнэ.

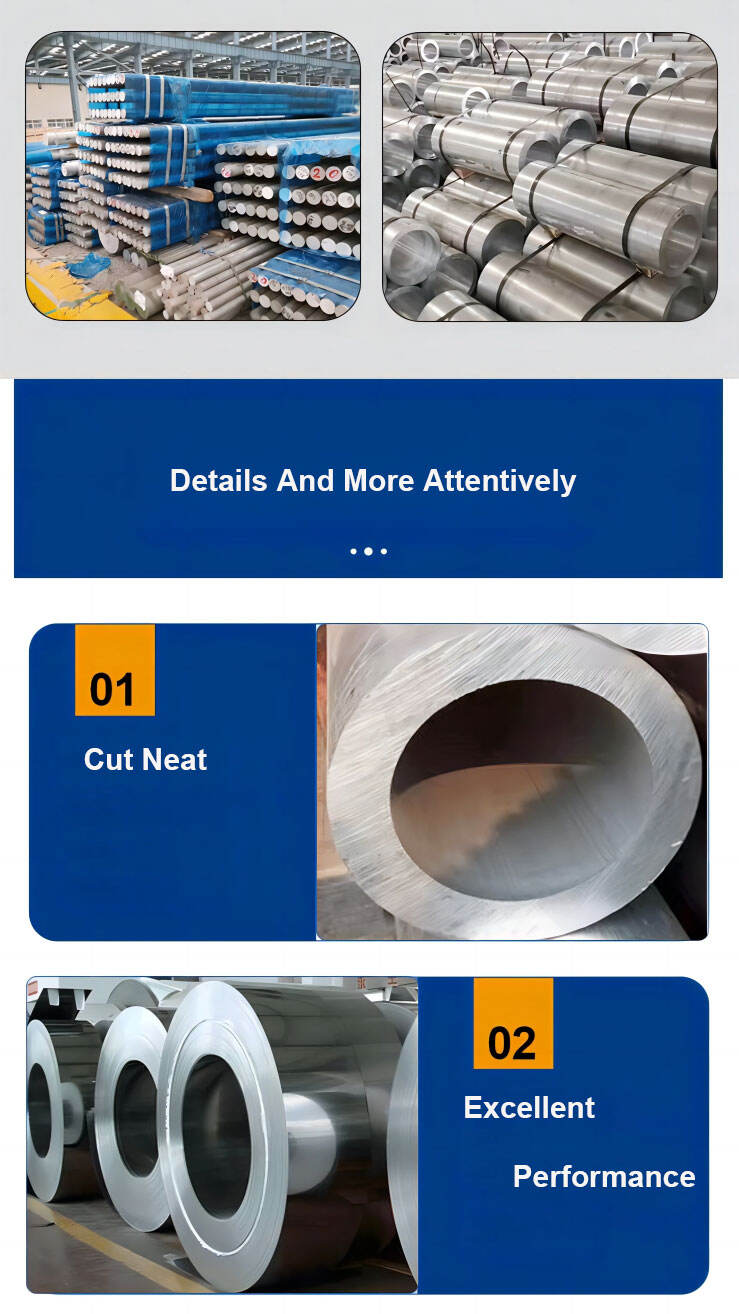

| Зүйл | Болон бар (Нисэх санаагаар) | |

| Тодорхойлолт | Дөнгөв төмөр | Дiamетр: 3mm~800mm эсвэл зөвшөөрөгдсөн |

| Квадрат төмөр | Хэмжээ: 4mm*4mm~100mm*100mm эсвэл зөвшөөрөгдсөн | |

| Шөнөө төмөр | Дээвэр: 2mm~100mm, Өргөн: 10mm~500mm. Зөвшөөрөгдсөн | |

| Гексагональ | Хэмжээ: 2мм~10мм эсвэл зөвшөөрөгдсөн | |

| Урт | 6м, 5.8м, 3м эсвэл шаардлагатай дагуу | |

| MOQ | 1 тонн | |

| Ангилал | 200 серия: 201/202 300 серия: 301/304/304L/305/309S/316/316L/316Ti/317L/310S/347/347H | |

| 400 серия: 405/409/409L/410/420/430/444/447 duplex: 2205/2507/2520 | ||

| 600 серия: 630/631 | ||

| super:904L | ||

| Үнийн хугацаа | Эх оронд худалдан авах, ФОБ, СФР, СИФ, СНФ | |

| Баглаа боодол | 1. өрөөний хэсгүүд дээр хоолойн өрөөтэй эсвэл 2. цаасан баримттай | |

| 3. шаргалын баримттай | ||

| 4. шаргалтай баримт | ||

| Харилцагчийн хүссэн тохирох эсвэл бүтээгдэхүүний хамааран пакинг | ||

| Гадаргын эдлэл | 8к зураас өнгөрсөн дүрс / шингээлт / BA / HL / гэх мэт | |

| Стандарт | GB, AISI, ASTM, ASME, EN, BS, DIN, JIS | |