Understanding Stainless Steel Coil Grades

Importance of Material Composition

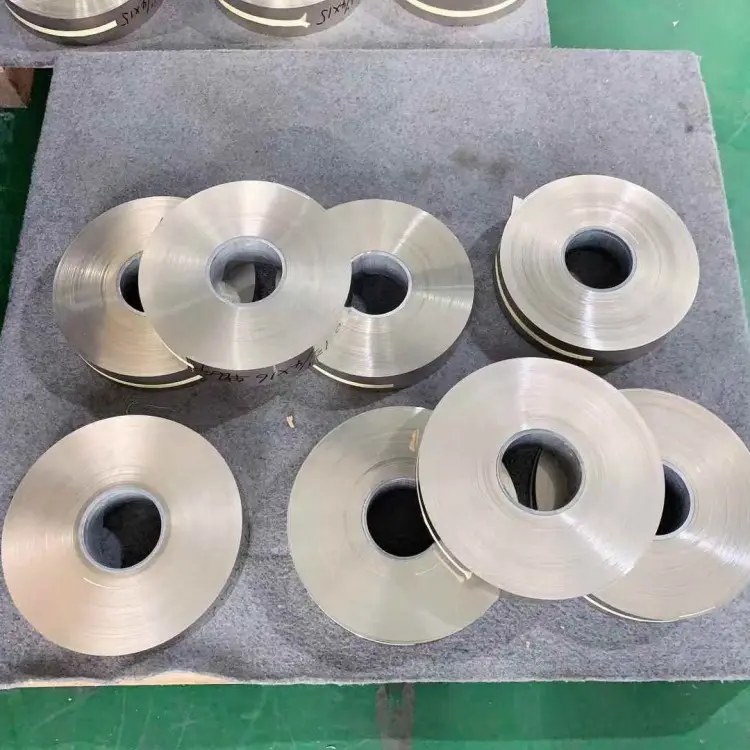

What goes into making stainless steel coils makes all the difference when it comes to strength and how well they stand up to rust. Basically, what separates one type of stainless steel from another boils down to the mix of stuff like chromium, nickel, and molybdenum inside them. And believe me, these small differences matter a lot when putting the metal to work in real world conditions. Take chromium for example – the more there is, the better protected against corrosion. Nickel and molybdenum do their own thing too, affecting things like toughness and durability. When someone looks at exactly what percentages make up these elements, they get a much clearer picture about which grade will work best for whatever job needs doing. Getting this right matters because nobody wants materials failing in kitchens, cars, or buildings where reliability counts.

Role of Chromium and Nickel

The properties that make stainless steel so special come down mainly to two elements: chromium and nickel. Chromium plays a key role because it gives stainless steel its famous resistance to rust and corrosion. Studies show that any alloy needs at least around 10.5% chromium to qualify as true stainless steel. Nickel works differently but just as importantly. It makes the metal more flexible and tough, which means manufacturers can shape and work with it much easier during production runs. The amount of nickel also has real world implications for cost and supply. Stainless steel coils with higher nickel content tend to cost more money and sometimes aren't as readily available when companies need them in bulk for their operations. For anyone shopping for stainless steel coils for industrial use, looking closely at what percentage of chromium and nickel they contain matters a lot. These elements affect not just how well the material performs in its intended application, but also how much it will ultimately cost over time.

304 Stainless Steel Coil: The Industry Standard

Properties: Corrosion Resistance and Formability

What sets 304 stainless steel coils apart is their remarkable ability to resist corrosion, especially when faced with acidic conditions that would eat away at other materials. This durability explains why industries dealing with constant moisture or chemical exposure rely heavily on this type of steel. The metal's formability is another big plus for manufacturers who need to craft complex shapes and components. Because it bends and forms easily without compromising structural integrity, engineers can design all sorts of parts from simple sheets to complicated machinery components. Looking at global production numbers gives an interesting perspective too. Around half of all stainless steel produced worldwide falls under the 304 category, which speaks volumes about how widely accepted and trusted this particular grade has become across different sectors.

Applications: Food Processing and Construction

When it comes to food processing, 304 stainless steel coils stand out because they stay clean so easily. The material can handle all sorts of cleaning agents and even harsh sterilization processes without losing its purity, something absolutely necessary when dealing with food products. Construction companies love this stuff too. It's strong enough to hold up under pressure but still looks great on buildings and structures people actually see daily, like elevator interiors or building exteriors. We've seen plenty of real world examples where these coils have lasted decades without showing signs of wear. From factory floors to high rise buildings, 304 stainless steel keeps performing while looking good doing it, which explains why so many industries continue to rely on this versatile material year after year.

316 Stainless Steel Coil: Enhanced Durability

Superior Chloride Resistance for Marine Use

Adding molybdenum to 316 stainless steel really boosts how well it stands up against chloride environments, which makes this alloy great for things around boats and ships. Studies show that structures built with 316 stainless last roughly 20 percent longer than those made from cheaper grades when they're out at sea or near the coast. That's why boat builders and coastal engineers rely on 316 stainless steel coils so much for their projects. After all, these materials need to handle constant saltwater exposure without corroding away too quickly.

Medical and Pharmaceutical Applications

Medical professionals and pharmaceutical companies often turn to 316 stainless steel coils because they stay clean longer and resist rusting even when exposed to harsh chemicals. This makes them ideal for things like pacemakers and scalpels where keeping everything sterile is absolutely essential. Most manufacturers know this stuff lasts way longer than other options, so they specify it whenever possible. Looking at recent trends across hospital supply chains shows a clear shift toward using 316 grade steel in operating rooms and labs. Regulations get tighter every year, and this particular alloy helps facilities meet those standards without breaking the bank on replacements. Its combination of strength and hygiene properties has basically made it the go to choice for anyone serious about maintaining high quality standards in healthcare settings.

The 316 stainless steel coil is not only durable but also versatile, catering to industries that demand reliability under harsh conditions and strict compliance standards. Whether in marine use or healthcare, its enhanced properties promise longevity and effectiveness.

430 Stainless Steel Coil: Cost-Effective Option

Heat Resistance and Aesthetic Appeal

Type 430 stainless steel stands out because it handles heat really well, which makes it great for things like ovens, ranges, and other kitchen gear that gets hot during operation. What many people don't realize is that this particular grade also has a nice shiny surface finish that looks good enough to display. Designers love working with it when creating countertops or decorative elements since it combines practicality with something visually appealing. The market seems to agree too there's been growing interest in affordable stainless steel alternatives recently, and 430 has become increasingly common in everything from appliance manufacturing to bathroom fixtures where both durability and appearance matter.

Automotive Trim and Appliance Uses

The automotive sector has long relied on 430 stainless steel for car trim because it offers good performance at a reasonable price point. Car makers can stick to their budgets while still getting decent quality materials that won't let them down. Appliance manufacturers love this steel too. Refrigerators, washing machines, even outdoor grills all benefit from the toughness and nice look of 430 grade steel. Recent market research shows more companies are switching to this particular stainless steel variant these days. It works well in so many different contexts, making household goods last longer and look better over time. From kitchen appliances to vehicle parts, 430 stainless continues to prove itself as a practical choice across industries.

201 Stainless Steel Coil: Balancing Affordability and Performance

Decorative and Consumer Goods Applications

201 stainless steel has become really popular for decorative purposes thanks to that shiny mirror finish and reasonable price tag. People love how it looks, which is why we see it all over consumer items like pots, pans, and even some furniture pieces. The thing is, this material strikes just the right note between what people want to spend and how good it looks when finished. Looking at what's happening in the market right now, there's definitely been an uptick in demand for 201 stainless steel among businesses trying to keep costs down while still delivering something attractive. What makes this alloy so great is how well it works across different applications. Manufacturers find themselves turning to 201 stainless steel time and again because they can make products that look nice without breaking the bank on materials.

Limitations in Harsh Environments

While 201 stainless steel coil offers good value for money and looks decent enough for many applications, it just doesn't hold up well in really tough environments. The truth is, when compared to better quality stainless steels, 201 simply isn't resistant enough to corrosion. This becomes a big problem in places where there's lots of salt air or industrial pollutants around, think coastal regions or factory floors. We've actually seen several instances where equipment made from 201 stainless failed after only a few months in these conditions. For anyone planning to install something outdoors near the ocean or in chemical processing plants, it makes sense to look at other stainless steel options instead. Grades like 304 or 316 offer much better protection against rust and degradation, which means less maintenance headaches down the road and components that last significantly longer before needing replacement.

Comparing Stainless Steel Coil Grades

Corrosion Resistance vs. Cost Analysis

When picking out stainless steel coil grades, it pays to know how corrosion resistance stacks up against price tags. Grades like 316 stand out for their ability to resist rust even in tough conditions, but let's face it – they cost a lot more money. Projects working with tight budgets might be tempted to go with cheaper options such as 304 or 201 stainless steel coils. The catch? Looking at cost comparisons across different grades shows those initial savings often vanish down the road because lower grade materials need more frequent maintenance and replacement. Industry pros tell us time and again that smart project management means weighing both how well something performs and what it will actually cost over its lifetime. Taking this longer view helps ensure whatever gets installed lasts longer while potentially saving thousands on repairs and replacements years later.

Choosing the Right Grade for Your Project

Picking the right stainless steel grade starts by looking closely at what the project actually needs, especially considering where it'll be used and what kind of strength is required. Industry groups have been pushing for a step-by-step method when making these decisions about stainless steel options. People need to check things like how hot or cold the environment gets, if there are chemicals around that might eat away at the metal, and just how much pressure the steel has to handle over time. Working directly with OEM specialists makes all the difference here. These experts know the ins and outs of different grades and can point out which ones work best for specific situations. Most engineers find that talking through requirements with someone who knows the materials inside out leads to better results. Plus, following this kind of hands-on approach naturally meets most industry guidelines while getting the job done right the first time.

Sustainability in Stainless Steel Production

Recyclability and Circular Economy Practices

Stainless steel coils can be recycled completely, which makes them pretty important when it comes to being green and saving resources. With all the talk these days about protecting our planet, this recyclability aspect puts stainless steel at the front of the line for companies trying to follow circular economy principles. The good news is that going green doesn't just help the environment either. Studies show that reusing old stainless steel saves around three quarters of the energy needed to make brand new steel from scratch. When factories encourage recycling programs, they cut down on waste while getting better use out of materials. This helps Mother Earth stay healthy and also keeps production costs lower in the long run for business owners.

Environmental Impact of Different Grades

Stainless steel comes in many different grades, and each has its own environmental footprint depending on how resources are extracted and how much energy goes into production. Looking at the whole life cycle shows something interesting about premium stainless steel grades. They tend to last much longer than cheaper alternatives, so even though they cost more upfront in terms of environmental impact, they actually end up being better for the planet in the long run because there's less need to replace them. The market is changing too. With new regulations pushing for greener manufacturing, companies making stainless steel coils are finding themselves under pressure to clean up their act. Many are investing in cleaner technologies now, knowing that customers want sustainable options and that markets will reward those who get ahead of the curve when it comes to eco friendly production methods.

FAQ

What are the key elements that define different grades of stainless steel?

Stainless steel grades are defined by the variations in elements like chromium, nickel, and molybdenum, which affect properties like corrosion resistance and mechanical strength.

Why is 304 stainless steel so popular?

The 304 stainless steel is popular due to its excellent corrosion resistance, formability, and adaptability, making it suitable for a wide range of applications, including food processing and construction.

Where is 316 stainless steel commonly used?

316 stainless steel is commonly used in marine environments, medical devices, and pharmaceutical equipment due to its enhanced chloride resistance and sterilization capabilities.

What are the limitations of 201 stainless steel?

201 stainless steel is less corrosion-resistant than higher-grade alternatives and is not suitable for harsh environments like marine or industrial settings with high salinity or pollution.

How can manufacturers benefit from using recyclable stainless steel?

Manufacturers using recyclable stainless steel can reduce waste, save up to 75% of energy in production, and adhere to circular economy practices, which are both environmentally and economically beneficial.

Table of Contents

- Understanding Stainless Steel Coil Grades

- 304 Stainless Steel Coil: The Industry Standard

- 316 Stainless Steel Coil: Enhanced Durability

- 430 Stainless Steel Coil: Cost-Effective Option

- 201 Stainless Steel Coil: Balancing Affordability and Performance

- Comparing Stainless Steel Coil Grades

- Sustainability in Stainless Steel Production

- FAQ