Evolution of Industrial Materials

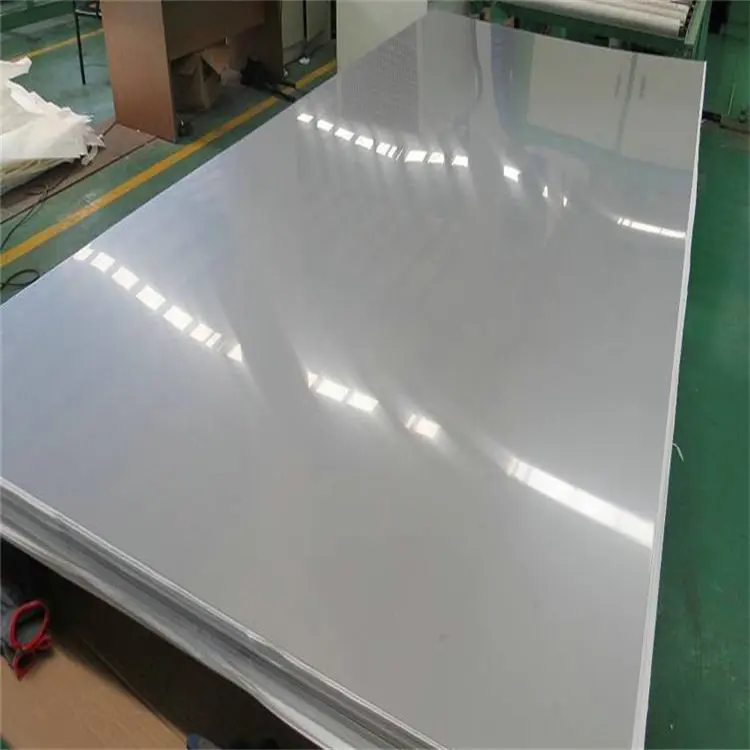

Over the past decades, industries around the world have witnessed a remarkable transformation in material usage, with stainless steel becoming increasingly central to modern manufacturing. A Stainless Steel Sheet is now a cornerstone in numerous sectors due to its strength, durability, corrosion resistance, and versatility. Its applications span from automotive and construction to household appliances and high-tech equipment. As global infrastructure and industrial growth accelerate, the demand for Stainless Steel Sheet has risen steadily, reflecting both technological advancements and changing market requirements.

Market Drivers for Stainless Steel Sheet

Industrial Expansion and Urbanization

Rapid industrialization and urbanization have created a significant need for durable and versatile materials. Stainless Steel Sheet meets these requirements by providing long-lasting performance in construction, transportation, and energy sectors. New urban centers require modern buildings, bridges, and facilities that can withstand environmental stresses, and Stainless Steel Sheet is often the material of choice for such projects.

Technological Advancements in Manufacturing

Advances in manufacturing technology have improved the production efficiency, quality, and variety of Stainless Steel Sheet. Modern rolling, finishing, and coating processes enhance the material’s corrosion resistance, surface smoothness, and strength, making it more appealing to industries that demand high-performance solutions. These innovations also allow producers to offer custom Stainless Steel Sheet options tailored to specific industrial applications.

Regional Trends Impacting Demand

Growth in Asia-Pacific Markets

The Asia-Pacific region has emerged as a key driver for Stainless Steel Sheet demand due to rapid industrialization, urbanization, and infrastructure development. Countries like China, India, and South Korea have seen large-scale construction projects, increasing the need for Stainless Steel Sheet in building facades, roofing, and industrial equipment. The rising middle class also fuels demand for household appliances that rely on high-quality Stainless Steel Sheet.

Expansion in North America and Europe

North America and Europe continue to see steady demand for Stainless Steel Sheet, driven by automotive, aerospace, and energy sectors. Manufacturers in these regions prioritize sustainability and long-term performance, which makes Stainless Steel Sheet an attractive material. Recycling initiatives and technological improvements in these markets also contribute to increasing the material’s adoption.

Applications Driving Stainless Steel Sheet Demand

Construction and Architectural Uses

Stainless Steel Sheet is widely used in construction and architecture for both structural and aesthetic purposes. From roofing and cladding to interior panels and handrails, the material provides durability, corrosion resistance, and a modern finish. Architects and builders value Stainless Steel Sheet for its combination of strength, low maintenance, and visual appeal, which supports rising demand in urban development projects.

Automotive and Transportation Industries

The automotive and transportation sectors increasingly rely on Stainless Steel Sheet for components that require corrosion resistance, high strength, and reduced maintenance costs. Stainless Steel Sheet is used in exhaust systems, fuel tanks, chassis, and decorative trims. The growth of electric vehicles and modern transport infrastructure further boosts demand for high-quality Stainless Steel Sheet.

Manufacturing Processes Influencing Supply

Rolling and Finishing Techniques

The production of Stainless Steel Sheet involves advanced rolling and finishing techniques to achieve precise thickness, smooth surfaces, and uniform properties. Cold and hot rolling processes, combined with annealing and pickling, enhance the material’s mechanical properties and corrosion resistance. These improvements in production processes ensure that Stainless Steel Sheet meets the diverse requirements of global markets.

Coatings and Surface Treatments

Coatings and surface treatments, including electropolishing and passivation, enhance the durability and aesthetic quality of Stainless Steel Sheet. These treatments improve corrosion resistance and surface smoothness, making the material suitable for critical applications in both industrial and consumer markets. The ability to customize finishes also expands the range of potential applications.

Economic and Trade Factors

Raw Material Availability and Costs

The demand for Stainless Steel Sheet is influenced by the availability and pricing of raw materials, such as nickel, chromium, and iron. Fluctuations in these resources impact production costs and, consequently, global market prices. Manufacturers must carefully manage supply chains to maintain consistent Stainless Steel Sheet availability for customers worldwide.

International Trade and Export Dynamics

Global trade agreements, tariffs, and import-export regulations affect the supply and distribution of Stainless Steel Sheet. Countries with advanced production capabilities often export large volumes, while emerging markets depend on imports to meet their industrial needs. Trade dynamics directly influence the global availability and demand for Stainless Steel Sheet.

Sustainability and Environmental Considerations

Recycling and Circular Economy

Stainless Steel Sheet is highly recyclable, which makes it a sustainable choice for long-term industrial and architectural applications. The circular economy approach allows manufacturers to reclaim scrap Stainless Steel Sheet and reintroduce it into production without compromising quality. This sustainability aspect appeals to environmentally conscious consumers and businesses.

Energy Efficiency in Production

Modern production of Stainless Steel Sheet emphasizes energy efficiency, reducing environmental impact while maintaining high-quality output. Techniques such as electric arc furnace recycling and improved rolling processes lower energy consumption, making Stainless Steel Sheet an environmentally responsible choice for industrial applications.

Innovations Enhancing Stainless Steel Sheet Demand

Advanced Alloy Development

Research in metallurgy has led to the creation of Stainless Steel Sheet with specialized alloys that offer superior corrosion resistance, strength, and formability. These innovations cater to industries with demanding operational conditions, increasing the attractiveness of Stainless Steel Sheet in global markets.

Smart Manufacturing and Customization

Industry 4.0 and smart manufacturing technologies allow for precise customization of Stainless Steel Sheet. Automated quality control, real-time monitoring, and advanced production techniques enable manufacturers to meet specific requirements, driving further adoption in sectors like aerospace, automotive, and electronics.

Challenges and Opportunities in the Market

Supply Chain Disruptions

Despite growing demand, supply chain disruptions can impact Stainless Steel Sheet availability and pricing. Factors such as raw material shortages, geopolitical tensions, and logistics challenges pose risks. Companies focusing on resilient supply chains gain a competitive advantage in meeting global demand.

Emerging Market Opportunities

Developing regions present significant opportunities for Stainless Steel Sheet expansion. Infrastructure projects, industrialization, and urbanization create a continuous need for durable materials. Strategic investments in these markets allow manufacturers to capitalize on rising demand and broaden their global footprint.

Future Outlook for Stainless Steel Sheet

Projected Market Growth

Analysts predict continued growth in global Stainless Steel Sheet demand due to ongoing industrialization, urbanization, and technological advancements. Sectors such as construction, transportation, energy, and consumer goods will continue to drive this trend, reinforcing the material’s essential role in modern industry.

Long-Term Industry Trends

Sustainability, recycling, and advanced manufacturing technologies will shape the future of Stainless Steel Sheet. Companies investing in eco-friendly processes, innovative alloys, and smart production methods will be well-positioned to meet evolving global demand. The combination of performance, durability, and environmental responsibility ensures a promising long-term outlook.

FAQ

What factors contribute to the rising demand for Stainless Steel Sheet

Industrial growth, urbanization, technological advancements, and increasing applications in construction, automotive, and consumer goods are the primary drivers for Stainless Steel Sheet demand.

Which industries utilize Stainless Steel Sheet the most

Key industries include construction, automotive, transportation, aerospace, energy, and household appliance manufacturing, all of which benefit from its strength, durability, and corrosion resistance.

How does recycling impact Stainless Steel Sheet supply

Recycling Stainless Steel Sheet reduces reliance on raw materials, lowers production costs, and supports sustainable practices, contributing to consistent global supply and environmental benefits.

Are there new technologies enhancing Stainless Steel Sheet applications

Yes, advanced alloy development, electropolishing, passivation, and smart manufacturing technologies enhance performance, corrosion resistance, and customization options for Stainless Steel Sheet in diverse applications.

Table of Contents

- Evolution of Industrial Materials

- Market Drivers for Stainless Steel Sheet

- Regional Trends Impacting Demand

- Applications Driving Stainless Steel Sheet Demand

- Manufacturing Processes Influencing Supply

- Economic and Trade Factors

- Sustainability and Environmental Considerations

- Innovations Enhancing Stainless Steel Sheet Demand

- Challenges and Opportunities in the Market

- Future Outlook for Stainless Steel Sheet

- FAQ